Today I had a nice phone conferance with Thomas and Jan from Metaio. Jan is the author of the Augmented Reality Blog. Jan had contacted me after reading my writeup about the use of AR in manufacturing based on a Microsoft video. Thomas is one of their designers and has experience with automotive manufacturing. And I’m looking for applications of AR to improve production at my Toyota casting plant.

The basics of our discussion was how to apply AR concepts to a manufacturing enviroment. The advantage I see for AR in a production enviroment is it brings complex levels of information to a real time enviroment. Many of the challenges of running a factory is getting the right information to the right people to make the right decisions. Every day people must make complex decisions, often with limited information, to perform their job. We apply many systems to these operations to ensure we’re producing a quality product at a good price, but often times we waste efforts because everyone doesn’t have the information they need at the moment they need it.

The combination of real time information in a production enviroment can reduce waste and improve quality if done correctly. One example I can illustrate this example is with die repair. We use steel dies for creating our castings and the dimensions of these dies need to be held tight tolerances of less than 0.20mm. This means we must constantly repair our dies because of wear from the aluminum (aluminum is corrosive to steel).

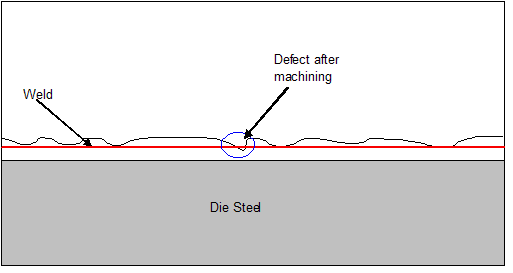

When we have to repair our die, we first have to weld it, then we machine it back to the required dimensions and then we check the quality. If we make a mistake, we have to go back to the beginning and start over. A common mistake is not putting enough weld material down, so when the weld is machined back to standard, gaps are created from the missing weld. This picture illustrates the example:

Using AR we can superimpose the correct dimension of the final shape over the worn die, so the welder knows if he’s put enough weld material on the die. This gets the right information to the right person at the right time. Before we had the right information, but we didn’t get it to the right person until much later in the process, so effort was wasted in between.

This is one small example of using AR in a production enviroment. And though we only had a brief discussion today about potential applications, my mind has been a-whirl about other possibilities, so I’m looking forward to working with Thomas and Jan to explore the potentials of this fledgling technology.

[…] AR for Industry 14.04.2009 | Posted in Computer World Today I had a nice phone conferance with Thomas and Jan from Metaio . Jan is the author of the Augmented Reality Blog . Jan had contacted me after reading my writeup about the use of AR in manufacturing based on a Microsoft video. Thomas is one of their designers and has experience with automotive manufacturing. And I’m looking for applications of AR to improve production at my Toyota casting plant. The basics of our discussion was how to apply AR concepts to a manufacturing enviromen See the article here: AR for Industry […]

[…] Carpenter on AR concepts to a manufacturing enviroment. I’ve just found his blog, and his other posts are interesting as […]

[…] 22, 2009 Following this claim by Rouli and inspired by a chat with Thomas I wanted to post something completely different this time. And maybe there will evolve a little […]